Grains, Oils & Condiments

In the grains, oils & condiments industry, metal contaminants pose risks throughout production:

Grain Processing (e.g., wheat, rice):

Harvesting may introduce field debris (e.g., broken wires, machinery parts, or nails).

Conveyor belt fasteners or damaged sieves during transport/storage can shed stainless steel fragments.

Oil/Condiment Production:

High-speed equipment (e.g., crushers, oil press bearings) generates metal particles due to wear.

Fractured vibrating screens or pipeline fragments may contaminate final products (e.g., flour, chili powder).

Impacts:

Production: Metal debris damages grinding rollers and clogging filling valves

Consumer Safety: Detected metal triggers compensation and irreversible brand damage.

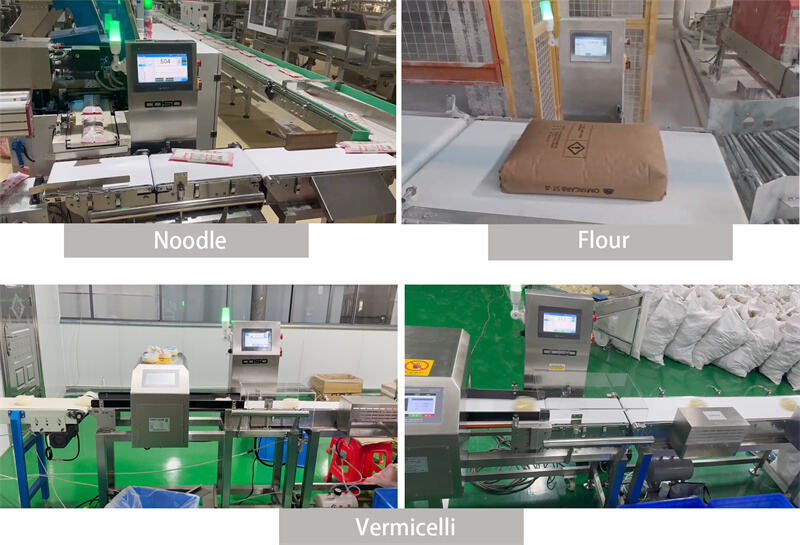

Our metal detectors can help with this.

And in this industry, precise filling control is critical. The auto-checkweigher utilizes high-accuracy sensors to monitor product weight in real-time, significantly reducing material waste. When underweight or overweight products are detected, the system triggers automatic rejection to ensure compliance with specifications.

Furthermore, the device can record product weight data which helps plant manager know about production situation.

We can also help with this.

Dongguan Coso Electronic Tech Co., Ltd.