Pharmaceutical

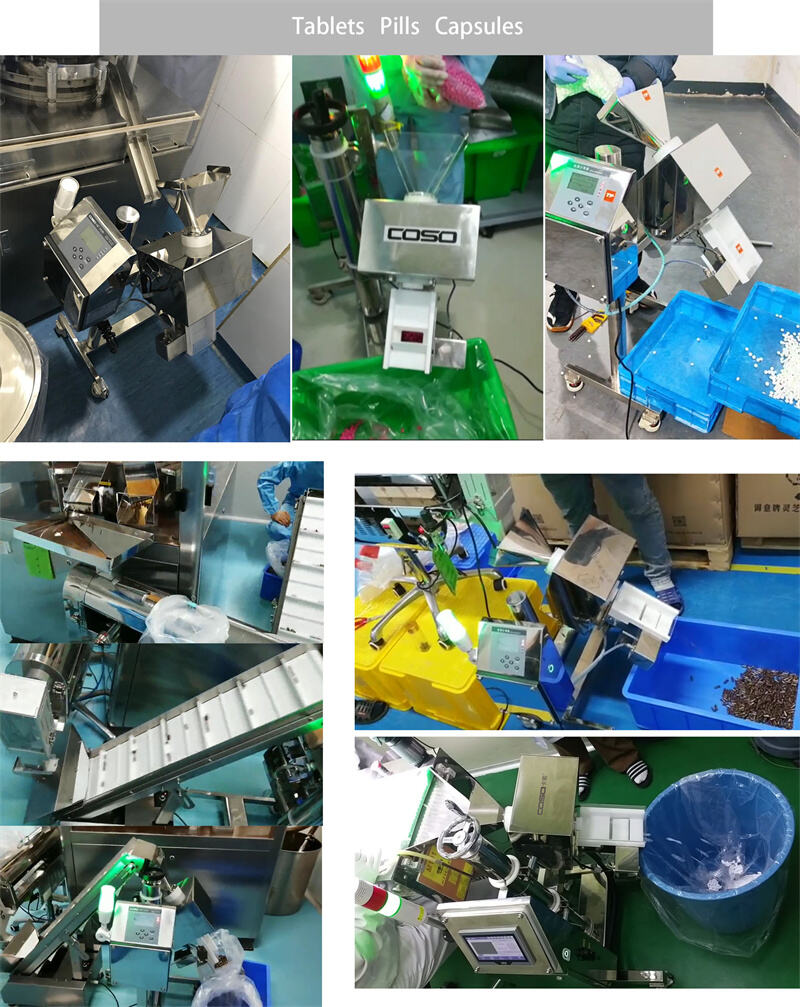

The pharmaceutical industry demands exceptionally high product quality standards. For oral solid dosage forms like tablets and capsules, even trace metal contaminants (e.g., iron shavings, stainless steel particles, or equipment wear debris) can pose serious risks - potentially lacetating the difestive tract or disrupting drug release mechanisms, compromising efficiency and patient safety. Metal impurities primarily originate from two sources:

Raw materials: Active pharmaceutical ingredients or excipients (e.g., starch, lactose) may carry metallic residues.

Production equipment: High-precision machinery (e.g., tablet presses, capsule fillers, polishers, sieving machines) can generate metal fragments due to friction or aging. Without intervention, these contaminants accelerate equipment wear, raise maintenance costs, or even halt production lines, resulting in significant financial losses.

To address this, our free-fall metal detector (metal separator) seamlessly integrates into pharmaceutical production lines. It employs high-sensitivity sensors to accurately identify ferrous, non-ferrous, and stainless-steel impurities. The system automatically rejects contaminated pills in real time, ensuring batch consistency.

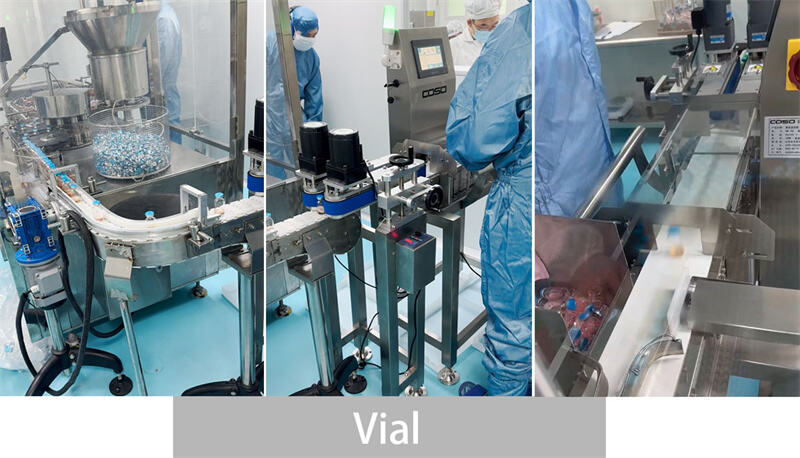

And in the pharmaceutical industry, the fill accuracy of vials critically impacts drug quality and patient safety. Since vial filling typically relies on peristaltic pumps or time-pressure systems, its precision is susceptible to multiple variables, including liquid viscosity changes (e.g., increased viscosity at low temperature), temperature fluctuations, and mechanical wear (e.g., pump tubing degration).

Underfilling may lead to the product being classified as substandard. Conversely, overfilling risks patient overdose.

Key Roles of High-Precision Checkweighers in Vial Inspection:

Reject empty/leaky vials: Detect weight differences to ensure liquid presence in every vial.

Identify underfills: Catch low-dose vials caused by partial needle clogging (e.g., due to crystallization or air bubbles).

Compliance & cost efficiency: Provent batch rejections while aligning with regulations.

And the medical laundry industy handles high-risk textiles such as hospital linens, surgical gowns, dressing towels, and protective clothing, which may contain hazardous metal contaminants, including:

Surgical remnants: Unremoved suture needles, syringe needles, scalpel blades, and orthopedic bone fragments.

Accidental items: Coins, keys, or paperclips left behind by patients or medical staff.

Risks or Undetected Metal Contaminants:

Human Safety Hazards:

1.Laundry workers may suffer needlestick injuries, increasing exposure to bloodborne pathogens (e.g., HIV, HBV).

2.Patient could sustain cuts from blade fragments, leading to infections or legal liabilities for healthcare providers.

Operatianal & Equipment Risks:

1.Mechnical damage: Metal debris lodged in drum bearings, conveyors, or ironing rollers accelerates wear-and-tear or catastrophic breakdowns.

2.Clogged water systems: Fine metal particles obstruct filtration, reducing wash efficiency and increasing downtime.

3.Fire hazards: Metal-on-metal sparks in high-temperature dryers may ignite lint accumulations.

Why Metal Detectors Are Essential:

Advanced detection: Can identify ferrous and non-ferrous metals with high precision.

Automated rejection: Integrated sorting systems remove contaminated textiles before washing cycles, ensuring compliance.

We provide tailored metal detection systems to help medical laundries enhance safety standards, protect personnel, and optimize operatioonal continuity.

Dongguan Coso Electronic Tech Co., Ltd.