Have you ever wondered how factories weigh products when they are being manufactured? And this is where inline balancing machines come in! These unique machines are capable of weighing products as they travel on the production line, making the entire process of weighing very fast and easy. The inline machines perform the weighing seamlessly during production rather than pausing everything to weigh items.

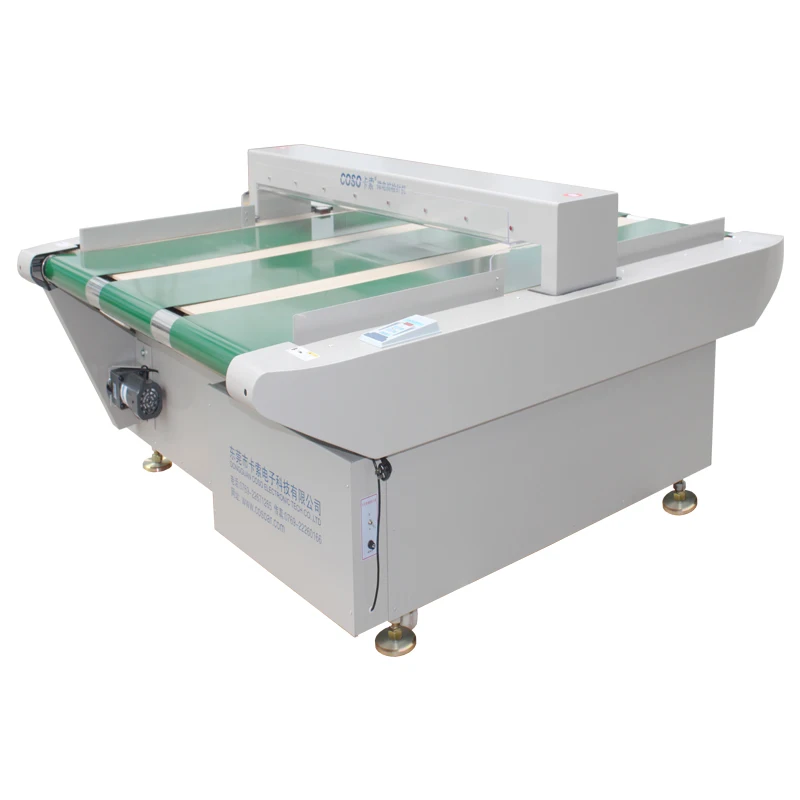

One of the recognized companies manufacturing these inline weighing instruments is COSO. Their machines are designed to weigh products with precision, meaning the right weight is reflected on the scale each and every time. This precision is extremely critical as customers will only receive products according to their expectations. As for the measurement, if a product is supposed to be of a certain weight, it better be, otherwise customers will be unhappy with the product they purchase.

Inline weighing machines from COSO are designed to be incorporated to the production lines without causing any delay. That allows products to be weighed during the making process without having to stop the machines and disrupt the production line. This not only cuts down on time but also lessens the possibility of human error that may occur in weighing items manually. It helps factories to minimize the gap of delay and keep the things rolling because the machines keep working.

COSO Inline conveyor scales are designed for high speed and accuracy operations. That means products can be calculated within a blip of a second, eliminating a time-consuming and labor-intensive manual weighing process. Therefore, manufacturers can minimize their costs while reducing the production cost eventually leading to much lower price for customers. Everyone wins in that equation!

Ensuring consistent quality is an extremely crucial aspect of manufacturing. It helps to ensure that the products are produced correctly and to standard. Inline weighing machines help improve quality control as they ensure that products are within the correct weight specifications every time.

Inline weighing machines from COSO are very precise and reliable, with integrated weighing machines positively affecting the consumer's packing line. This allows for weighing to be done consistently, ensuring that the required weight is achieved. Correct weighing of products improves the quality checks and limits the risk of sending out products that do not meet the weight standard. This is vital to ensure customer satisfaction while also upholding your reputation for quality.

Inline weighing machines from COSO are designed for precision and accuracy This allows for weighing products to accurate weight without any physical assistance or interference. Factories benefit from automation of the weighing process by saving time, reducing the potential for error that can accompany manual weighing, and so forth. This guarantees that weight requirements are achieved every time, aiding in production flow.

Dongguan Coso Electronic Tech Co., Ltd has been manufacturing products more than 18 years. We have produced various types metal detectors, check weigher machines, well as other electronic devices according to the specifications the customers. have our own engineering teams can inline weighing machinesolutions quickly. can customize conveyor belt height and width from floor to belt quickly as well as all types reject systems to suit customer's usage. machines trade with clients in more than 80 countries across the globe.

Dongguan Coso Electronic Tech Co., Ltd has been manufacturing electronic items since 2005. Our manufacturing facility covers area of 4000 square metres. We have over 18 years of experience in making all kinds of metal detectors, including conveyor metal detectors and free fall metal detectors. Checkweigher machines are also available to satisfy the customer's needs. Coso's in-house design and engineering team is able quickly offer solutions our customers. Our machines sensitive and are user-friendly. We offer a one-stop shopping service that includes a wide range of products, including metal detectors, checkweighers, metal separators and X-ray inspection devices. We also have a systemic after-sales team who can solve issues with customers.

Dongguan Coso Electronic Tech Co., Ltd is professional manufacturer, established in 2005. We offer professional solutions to meet the needs of customers with competitive price. Our highly skilled engineering and design team allows us to design machines according the budget of the customer and needs. Our employees are also highly experienced and certified, which ensures the high-quality of our equipment and prompt delivery. Prior to delivery, every machine will have quality inspection. Our machines have low maintenance and use cost. The machines are all covered by year warranty, and within warranty, no spare parts are provided. The machines we use are CE certified and can exported to more than 80 countries.

Dongguan Coso Electronic Tech Co., Ltd a professional manufacturer from 2005, our metal detector machine highly inline weighing machine and high-quality. machine is easy operate due its modular design and a user-friendly HMI. We'll provide our customers with operation guides and operating videos instruct users on how to use machines. Every machine comes with one-year guarantee, and spare parts are available for free. the machine breaks, changing spare parts can easily solve problems.