Are you tired of one's apparel industry output containing unwanted metallic parts? Worry no more, COSO metal detector machine for garment industry can help you eliminate this issue. A Metal Detector Machines is a computer device that detects metallic substances in your garment industry services and products before they get delivered. They are used in the apparel industry to remove contaminants that are metallic steel zippers, needle components, and buttons. We will talk about advantages, innovation, safety, use, exactly how to utilize, service, quality, and application of metal detector machines.

One of the primary advantages of COSO garment metal detector machine is their ability to detect even the smallest metallic contaminants in your fabric products. This makes them efficient and reliable, reducing the risk of any defective items reaching your warehouse.

With ongoing technological advancements, COSO metal detector for garment industry have become more sophisticated, accurate, and user-friendly. They can detect metal contaminants of various sizes, shapes, and materials, ensuring you deliver flawless items to your customers.

Metal Detector Machines eliminate the risk of damages caused by metallic shards or fragments that could harm the end-users of your garments. By ensuring that the final product is free from metal contaminants, you ensure the well-being of your customers, reducing liability and safety concerns with COSO metal detector machine.

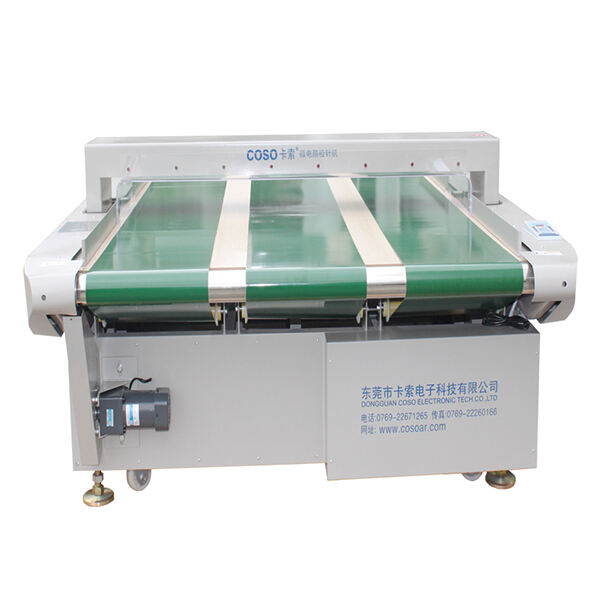

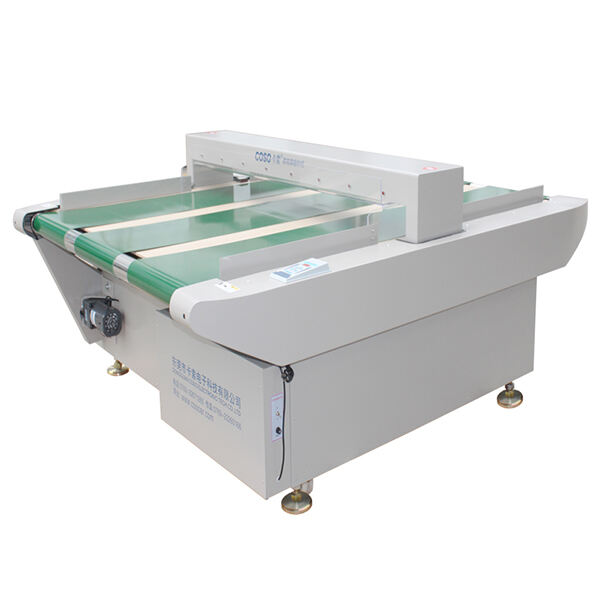

Metal detector machines are utilized in the garment industry to inspect products for any metallic contaminants before packing or shipping them to consumers. As a user, you place your garment product on a conveyor belt, which moves it through a scanner that detects metals, contaminants, and separates them from the good products using COSO garment metal detector.

Dongguan Coso Metal detector machine for garment industryTech Co., Ltd is a professional manufacturer since 2005 Metal detectors from is highly sensitive and high-quality. machine is easy operate due its the modular design as well as user-friendly HMI. To train customers on how to operate the machines we'll provide them with manuals for operation and videos. machines come with a 1-year warranty, and spare parts readily available no cost. If machine fails can be fixed replacing the spare part.

Dongguan Coso Electronic Tech Co., Ltd has been a manufacturer of electronic items since 2005. Our manufacturing facility covers area of 4000 square metres. We have more than 18 years experience in producing all kinds of metal detectors, like conveyor metal detectors as well as free fall metal detectors and checkweigher machine to satisfy the needs of our customers. Coso has its own engineers and design team that will provide the right solutions for customers quickly. Our machines extremely sensitive and easy to operate. We offer one-stop purchasing of different products such as metal detector, checkweigher, metal separator and X ray inspection system. Additionally, we offer a comprehensive after-sales service to assist customers solve problems.

Dongguan Coso Electronic Tech Co., Ltd is professional manufacturer, established in 2005. We can offer solutions that are professional to meet the requirements of our customers at competitive cost. Our experienced design and engineering team allows us customize machines according the customer's budget and specifications. Our employees are also highly experienced and certified, which ensures the high-quality of our machines and on-time delivery. Before delivery, each machine will undergo a quality check. Our machines have low cost of usage and maintenance. All machines come with 1 year warranty and no spare parts are available within the warranty period. Also, our machines come with CE certificates and are exported to over 80 countries around the globe.

Dongguan Coso Electronic Tech Co., Ltd has been manufacturer for over 18 years. have produced every kind of Metal detector machine for garment industrydetector well as check weigher machines as well other electronic devices according to the needs of the client. And have own engineer teams provide suitable solutions customers rapidly. can tailor conveyor belts' width height from floor to belt quickly along with all sorts rejection system according to customer's usage. More than 80 countries trade with our equipment.

For your Metal Detector Machines to function effectively, it's essential to follow proper usage procedures. As a user, you should switch the machine ON, input the product data, adjust the sensitivity range of COSO metal detection equipment, and calibrate the device to the type of item being examined. It's important to place the products correctly on the conveyor belt at a steady pace to avoid any errors.

A Metal Detector Machine is a precision instrument that must be regularly maintained to continue functioning at peak performance. It's essential to service the machine, replace any worn-out components, and lubricate it to prevent corrosion. Scheduling routine maintenance is highly recommended.

A Metal Detector Machine ensures accurate and consistent detection of metallic substances, reducing the risk of damage or liability issues in the event of any metallic contamination in your products.