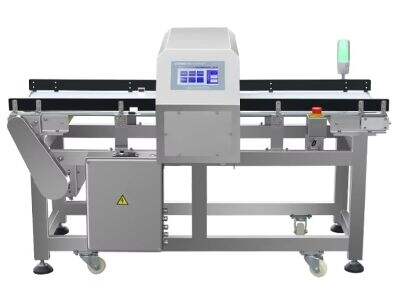

When you are in the supermarket buying that great snack or lunch, did you ever wonder how they do it? Lots of the food we love is made in places called food processing plants. These factories employ large machines to combine materials and make the delicious foods we love to eat. But did you know there is one important kind of tool that every food processing plant should have in order to ensure the food we eat is safe and healthy? That tool is an industrial metal detector, and it helps keep us safe and ensure our food is prepared to perfection.

Product Safety and Compliant with Industry Regulation

In the case of an industrial metal detector, one of its primary roles is ensuring the food we consume is safe. Occasionally, small bits of metal can mistakenly be mixed in with the food during the production process. If you were to eat one of these sharp pieces of metal they could harm your teeth or make you ill. That is why a giant metal detector is used to check the food as it travels through the processing plant. If a detector senses metal, it will activate an alarm to alert workers that a problem has occurred. This is what keeps us safe, and the rules and guidelines that the food industry has are met.

Avoid expensive recalls and Protect Your Brand

Have you heard of a recall on your favorite snack or beverage? At times, food companies have to recall their products from store shelves because something is wrong with them. “This can be very costly for the company and lead people to be concerned about whether it’s safe to eat the food. Food processing plants can catch any metal contaminants before the food gets packaged and distributed to stores by utilizing an Industrial metal detector. It prevents expensive recalls and protects brand image. When you know a company cares that food is safe, you’re more inclined to trust and buy what it sells.

Equipment Protection as well as Minimization of the Risk of Infection

Not only does an Industrial metal detector keep us safe, but they are also responsible for protecting the machines and devices inside a food processing plant. The food business is highly regulated, and if a piece of metal appeared to be in a product and go through the commercial machines, “it would blow up the machines and be a huge problem,” he said. With a metal detector to detect any metal before it goes through the machines, the plant can sidestep expensive repairs and downtime. It also minimizes contamination in the food, which can compromise the taste and quality of the end product. Provided that the equipment is properly cleaned and protection, the plant will operate even more smoothly and efficiently.

In fact, improving comprehensive quality control and production efficiency

Another advantage of food conveyor metal detectors at a food processing plant is that they are able to improve the general quality control and output efficiency. By spotting any metal contaminants so early, the plant can make sure the food being produced is top quality. This ensures that every package of food that arrives at stores is safe and appetizing for us to eat. What’s more, using a metal detector can aid the production process by promptly detecting and separating any inadvertently added metal. It makes the plant efficient and works for the hungry customers.

Peace of Mind for Buyers and Peace of Mind for Sellers

Finally, a metal detector being installed in a food processing company ultimately provides both you and me peace of mind, as consumers, as well as to the companies who make our food. We can have confidence selecting such products knowing that our favorite snacks and meals are made with those safety precautions in mind. For the manufacturers, a metal detector allows them to have a peace of mind that they are taking the appropriate measures to guarantee the quality and safety of their food. This assists them in developing a customer trust and establishing a good reputation of their brand. Without anyone feeling threatened or unhappy, all can eat without thinking that the food was prepared with anything other than care and respect.

Table of Contents

- Product Safety and Compliant with Industry Regulation

- Avoid expensive recalls and Protect Your Brand

- Equipment Protection as well as Minimization of the Risk of Infection

- In fact, improving comprehensive quality control and production efficiency

- Peace of Mind for Buyers and Peace of Mind for Sellers